News-B&D Technology and Huawei Cloud Joint Premiere: The "Intelligent Revolution" Ushers in Cost Reduction for Manufacturing Public Auxiliary Facilities!

From June 20th to 22nd, 2025, the Huawei Developer Conference 2025 was held in Songshan Lake, Dongguan, China.

On June 21st, at the highly anticipated Huawei Developer Conference, Mr. Guo, Vice Chairman of Guangdong Baldor Technology Co., Ltd., and Mr. Huang, CIO, were invited to attend. Meanwhile, Mr. Huang delivered a wonderful speech titled "B&D Technology x Huawei Cloud Intelligent Facilities Cloud Platform: Empowering the Digital and Intelligent Transformation of Manufacturing Public Auxiliary Facilities" at the forum "Huawei Cloud Product Digital Intelligent Collaboration Solution: Opening up the Upgrading Path for Manufacturing."

▲ Mr. Huang, the CIO of B&D, gives a product presentation

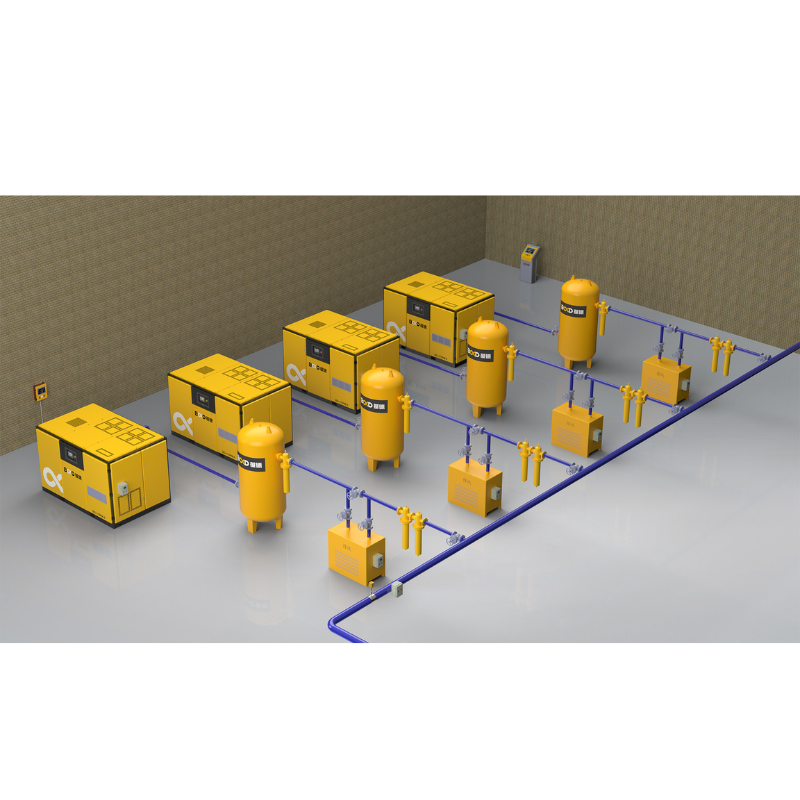

Guangdong Baldor Technology Co., Ltd., a leading enterprise in China's intelligent permanent magnet variable frequency air compressors and a one-stop service provider for industrial digital intelligence and energy conservation, has officially launched the "Huawei Cloud Intelligent Operation and Maintenance and Energy Management Solution for Public Auxiliary Facilities" in collaboration with Huawei Cloud. By deeply integrating cloud computing, AI large models, and IoT technologies, this solution addresses the pain points of "high energy consumption, low efficiency, and difficult maintenance" in manufacturing public auxiliary facilities (air compression, refrigeration, photovoltaics-storage-charging, power distribution, etc.), pressing the "accelerator button" for cost reduction and efficiency improvement.

Huawei Cloud and B&D Technology leverage their respective advantages in industrial energy conservation and big data, representing not only a deep collaboration in technological ecology but also a key milestone in the "public auxiliary facilities revolution" during the digital transformation of the manufacturing industry.

Data shows that energy consumption of public utility facilities in China's manufacturing industry accounts for 35%-50% of total factory energy consumption. However, under traditional management models, these facilities face three major issues:

Severe energy efficiency waste: The majority of enterprises manage public utility equipment in a rudimentary manner without proper tools for control, resulting in 10%-30% energy waste;

High maintenance costs: Delayed response to equipment failures leads to production line losses due to equipment downtime;

Data silos: Systems operate independently, preventing holistic optimization, and energy-saving renovations are based on ad-hoc decision-making.

Relying on Huawei Cloud's full-scenario cloud computing services and B&D Technology's 20-year expertise in industrial energy conservation (covering 1,000+ manufacturing enterprises and 30+ industry scenarios), the two sides have built an integrated "end-edge-cloud-application" system:

1. Full-element Access:

B&D Technology's intelligent collection captures operation parameters (voltage, current, pressure, temperature, etc.) from equipment like air compressors, refrigeration units, and water pumps. Compatible with over 98% of mainstream industrial equipment protocols, it breaks down data silos entirely. Pilot data from an automotive parts enterprise shows that after equipment integration, data collection coverage increased from 40% to 100%.

2. AI-driven Energy Saving:

Leveraging Huawei Cloud's big data and AI algorithms, the solution provides optimal equipment control strategies to keep operations within the most energy-efficient range, achieving carbon reduction. For example, it dynamically adjusts equipment operation based on external factors like production scheduling and gas consumption—such as reducing air compressor pressure during non-peak hours.

3. Digital Visibility:

Through the 3D visualization engine co-created by B&D Technology and Huawei Cloud, real-time equipment status is presented. Managers can check real-time load of the specific air compressor or flow distribution in a pipeline by clicking on a mobile phone or large screen, truly enabling "remote operation and control."

4. Full Lifecycle Service:

Unlike traditional "break-fix" maintenance, the platform uses predictive maintenance algorithms to warn of issues like bearing wear and motor aging, reducing downtime by over 80%. It generates "energy efficiency diagnosis reports" to help enterprises identify high-energy-consuming processes and inefficient equipment—for instance, an electronics manufacturer saved USD68355 annually by replacing just 3 inefficient air compressors after applying the solution.

comment (02)

Jenny Wilson

19 June 2023Rating:

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat aute irure dolor in reprehenderit.

Marvin McKinney

19 Feb 2024Rating:

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat aute irure dolor in reprehenderit.